'It is exciting to notice how our customers are using the online equipment', states Philip Ainge, Transvac's Company Development Manager. Please for support with these computations in the mean time. Our software for liquefied / gas Ejectors is under growth, including our super-high compression variety of Liquid Aircraft Compressors (LJCs). Ejector design using Fluent CFD software. By Computational Fluid Dynamics Software. OPTIMIZATION OF A HIGH-EFFICIENCY JET EJECTOR BY COMPUTATIONAL FLUID DYNAMICS. Make sure you note that Vapor Ejectors are usually not protected in the fuel software, please get in touch with us for steam sizing. Programs for gasoline / gasoline and water / water Ejectors are usually available online - make sure you request a exclusive login by completeing the form below. Online Ejector Screening process Software Transvac designers have created an on the internet software programme to enable our customers to operate preliminary Ejector screening, to make the technologies more available to Designers across the essential oil gas and process industries. Then admixture of working and suctioned substance with the steady pressure and velocity profile leaves the › ▆ ▆ ▆ Ejector Design Calculation Software ▆ ▆ ▆ reduced velocity) as well as increase in liquid pressure was caused.

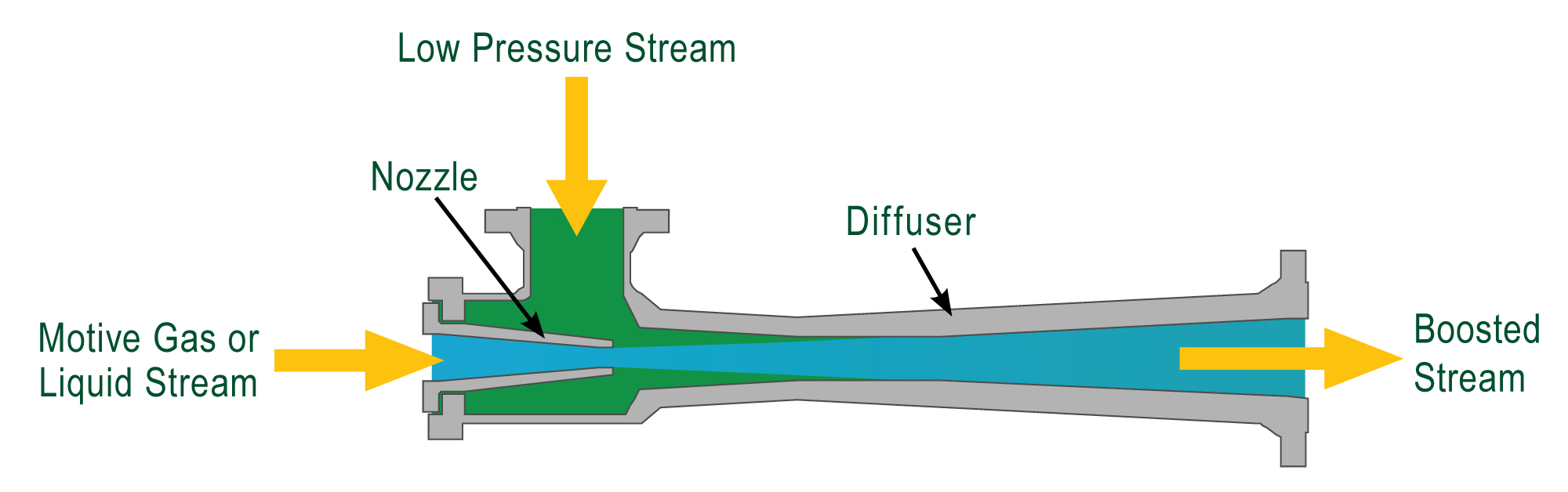

At the inlet of the divergent section (expanding channel) there must be subcritical flow according to Huguenot theorem, so that compression (i.e. In case of subcritical flow, the mixing chamber has a shape of a cylinder and in case of supercritical flow it is tapered to slow down the flow. At the outlet of the suction chamber of the nozzle the admixture of substances has the same pressure but different velocity profile, that is to be conditioned in the mixing chamber. Thanks to that there is a negative pressure formed in the suction chamber and it begins to suck-in the secondary (driven) liquid. Due to expansion in the nozzle the pressure is dropped and the velocity of the primary liquid is increased. The ejector works on the principle that the working substance enters the suction nozzle, that can be either classical tapering or Laval’s one, downstream which there can be supercritical flow.

0 kommentar(er)

0 kommentar(er)